Allup Silica Restricted (ASX: APS) (“Allup” or “Firm”) is happy to offer an replace on works to progress growth of its 100%-owned McLaren Beneficial Heavy Mineral Sands (VHMS) Undertaking close to Balledonia, WA.

Abstract

- IHC Mining Consultants (IHC) has commenced preliminary levels of McLaren Mineral Sands Pre-Feasibility Examine (PFS) engineering design

- Preliminary design Scope based mostly on 10Mtpa throughput to provide as much as 400,000tpa ilmenite product

- Earlier metallurgical check work accomplished by IHC Competent Individuals in 2018 demonstrates good ilmenite recoveries from a traditional mineral sands flowsheet

- Allup plans to begin infill drilling program at McLaren in This fall, 2024

- Environmental Assets Administration (ERM) appointed to plan infill drilling program and replace Mineral Useful resource Estimate (MRE) as soon as drilling outcomes are obtained.

- PFS anticipated to be accomplished throughout Q2 2025

Allup can also be making ready a drilling program for the undertaking in This fall CY24 to allow an replace of the prevailing Mineral Useful resource Estimate (MRE) in early 2025, and to research potential to extend the recognized useful resource.

Earlier IHC Metallurgical Testwork Outcomes

In 2018, IHC accomplished a metallurgical testwork program on a consultant pattern derived from a 14-tonne bulk pattern from the McLaren deposit. The pattern assayed roughly 7.2% heavy mineral. Mineralogical analyses of the heavy mineral point out it to include 56.3% ilmenites and better grade titanium minerals similar to Leucoxene.

The IHC metallurgical check work program confirmed the fabric to be amenable to straightforward mineral sands processing methodologies, utilising typical mineral sands gear.

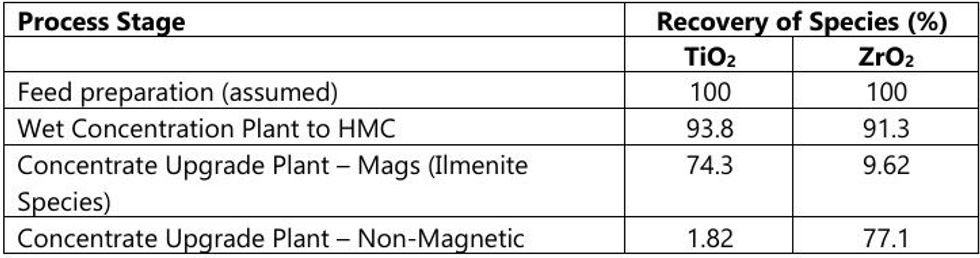

Desk 1: Outcomes from IHC testwork accomplished in 2018

Ilmenite restoration from WCP feed into the CUP Magnetic stream was ~75% of ilmenite, Altered Ilmenite and HiTi minerals. General restoration of rutile/anatase from the WCP feed into the non-magnetic focus was ~57% General restoration of zircon from the WCP feed into the CUP non-magnetic focus was ~70%.

Slimes settling was achieved utilizing addition of three% gypsum, leading to important enchancment in flocculant dosing charges, right down to 150-200g/t.

The check work produced last merchandise of:

- Ilmenite of an appropriate grade to be categorized as sulphate ilmenite

- Rutile of a typical high quality with 95.7% TiO2, 1.49% Fe2O3,

- Zircon of a typical normal zircon high quality, noting ranges of U + Th at 265ppm had been thought-about very low.

Flowsheet Improvement

The IHC 2018 check work resulted within the growth of a conceptual flowsheet utilizing conventional mineral sands separation methods. It consisted of three circuits, comprising:

- Feed Preparation – made up of hydrocyclones and a thickener used to settle and separate the slimes. The slimes fraction could be returned to the mining void together with the tails stream. The non-slimes portion could be fed to the WCP.

- Moist Focus Plant (WCP) – made up of a number of spiral levels (gravity separation) – the WCP course of produced a Heavy Mineral Focus (HMC) containing 89.1% heavy mineral, 25.9% TiO2 and 0.37% ZrO2.

- Focus Improve Plant (CUP) – screening to take away +425 µm materials (decided by check work to be barren), then a number of levels, primarily of magnetic separation.

The HMC produced within the WCP was processed by the CUP to provide a magnetic focus appropriate for an ilmenite course of circuit and a non-magnetic focus containing 90-95% Heavy Mineral.

Click on right here for the complete ASX Launch

This text consists of content material from Allup Silica Restricted, licensed for the aim of publishing on Investing Information Australia. This text doesn’t represent monetary product recommendation. It’s your accountability to carry out correct due diligence earlier than performing upon any info offered right here. Please confer with our full disclaimer right here.