ESA scientists have efficiently demonstrated 3D printing of a metallic half in area for the primary time.

3D printing in area poses challenges, as many strategies depend on gravity to place supplies in the course of the printing course of. It’s because when creating metallic constructions, molten metallic is commonly used as a part of the filament, or printable medium. In area, its habits may be unpredictable, which may end up in poor-quality objects, because the filament may shift or be positioned incorrectly because of the lack of gravitational forces.

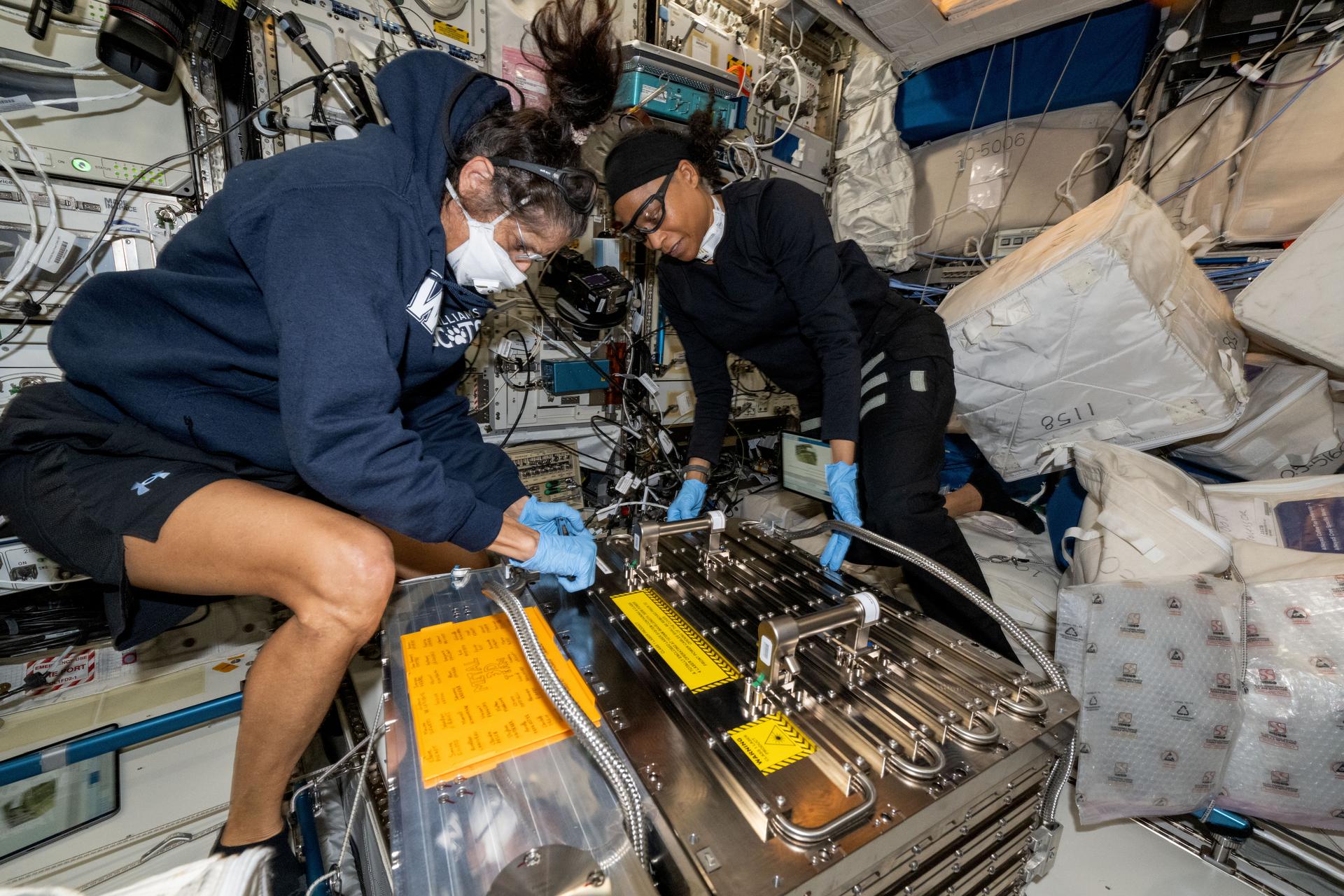

Scientists subsequently needed to adapt to work underneath these difficult situations, and the Worldwide House Station supplied the proper setting. ESA’s metallic 3D printer makes use of a chrome steel wire melted by a strong laser that reaches 2,192°F (1200°C) to create its molten metallic filament that will get deposited layer-by-layer to construct out a desired form.

By way of painstaking checks carried out over a number of months, the crew was lastly capable of alter the printer to its microgravity surroundings, producing the primary metallic half in area this August 2024. The crew plans to print two extra objects, then all three will probably be introduced again to Earth for high quality evaluation and future planning.

Associated: Future moon astronauts could 3D-print their provides utilizing lunar minerals

“With the printing of the primary metallic 3D form in area, ESA Exploration groups have achieved a big milestone in establishing in-orbit manufacturing capabilities. This accomplishment, made attainable by a world and multidisciplinary crew, paves the best way for long-distance and long-duration missions the place creating spare elements, building elements, and instruments on demand will probably be important,” mentioned Daniel Neuenschwander, director of Human and Robotic Exploration at ESA, in an announcement.

This groundbreaking know-how continues to broaden its purposes on Earth, revolutionizing fields comparable to drugs, trend, artwork, building, meals manufacturing and manufacturing. In area, as long-duration missions to the moon and probably Mars take form, astronauts will want a way of independently repairing or creating instruments or elements for equipment or constructions that may be troublesome to hold onboard a spacecraft, which have restricted capability.

Because the know-how advances, it might even someday allow the printing of latest tissues or organs, enhancing the power to maintain long-term area exploration—although we’re nonetheless many years away from this being viable.

3D printers in area are nothing new, as microgravity provides an fascinating surroundings for scientists to conduct experiments, develop higher 3D printing supplies, or create constructions troublesome to make on Earth. Nonetheless, what’s important about ESA’s latest announcement is that that is the primary time a 3D printer has efficiently produced a metallic half.

This functionality represents a significant milestone as, till this level, metallic elements for area missions needed to be produced on Earth and transported to orbit —a expensive and sophisticated a part of any mission.