Efficiency biking sits in a moderately distinctive place amongst vehicular sports activities. No one can purchase a Method 1 race automotive, and neither can any Tom, Dick, or Harry rock as much as a marina and put a down fee on an America’s Cup boat. With biking although, because of the Union Cycliste Worldwide governing physique insisting that each piece of apparatus used within the skilled peloton even be out there on the market publicly, one can, with deep sufficient pockets, order the identical bike as the professionals use.

There are after all some loopholes and gray areas; no sport is with out these they usually make for an attention-grabbing narrative for gear nerds. It’s common to see gear, particularly on the Olympic stage, priced so outlandishly that no one of sound thoughts would ever consider urgent the ‘purchase now’ button, hidden on the centre of a maze of menus and sub-menus to make issues much more difficult. Generally gear is solely ‘value on request’, or within the case of customized gear lead instances of a few years are quoted as a deterrent to make sure solely the nationwide group in query retains entry.

Ignoring the murky world of Olympic observe biking although, it’s comparatively simple to work out how a lot a WorldTour bike prices. You merely google all of the constituent elements, discover the costs for every, and do a little bit of including up. We’ve already carried out that bit earlier than although for Tour de France bikes. The brief model is {that a} WorldTour bike prices wherever between £12-13k, or $15-17k in freedom foreign money.

There’s extra to price than simply the worth tag nevertheless. There’s the price of manufacturing and transport, not simply of the bike and the parts, however of the uncooked supplies too. There’s middlemen, dealerships, and sponsors, that means there’s primarily three completely different prices: Price of a produced bike, price of a retail bike, price of a motorcycle to a group.

Within the coming sections, I’m going to try to demystify simply why bikes price as a lot as they do, drawing on a few of my very own expertise – I’m a mining geologist by coaching with loads of background in uncooked supplies, imagine it or not – and calling in consultants and people within the business to assist steer get as clear an image as I can. Broadly talking I’ll use the Pinarello Dogma F for instance all through. It is fabulously costly, raced on the WorldTour stage, and I’ve reviewed it not too long ago. Furthermore, Pinarello was comfortable to place somebody as much as chat with me concerning the prices concerned.

The figures I’m presenting right here will not be by any means meant to be gospel, however merely a greatest estimate taking in all the data I can discover. There’ll undoubtedly be areas the place I under- or over-estimate, and a few prices I can’t account for. The intention is solely to seek out out the prices concerned with producing such costly bikes, and whether or not they can justify their value.

Uncooked supplies

Bikes, and bicycle parts, are kind of totally made of 5 issues: Carbon, aluminium, metal, titanium, and rubber. I’ve written a primer on how bicycles are made for every of those supplies apart from rubber already if you’d like a little bit of homework. There are undoubtedly extra, however that’s very a lot the lion’s share now that no one is racing magnesium Pinarello Dogmas anymore. If you would like a enjoyable truth, the final non-carbon bike to win the Tour de France (for those who ignore Floyd Landis’ really successful it on the time) was a magnesium Pinarello Dogma in 2006.

Carbon fibre makes up the majority of high-end frames, forks, cockpits, rims, and a good few crank arms, brake levers, and different small tech too like bottle cages. It’s totally produced from oil. The chemistry is a bit advanced for the scope of this text, however in essence, a steady polymer thread just like nylon is spun out after which handed by way of a furnace or two to carbonise it – actually flip it into carbon. These fibres can then be bundled collectively to create a carbon weave, lined in a little bit of resin in a mould, baked, and there you’ve gotten it.

It’s comparatively easy, and at its most simple the uncooked materials (taking Brent Crude because the oil value) is value about 77 {dollars} a barrel.

Let’s assume for the sake of argument that 4kg of a 6.8kg race bike is comprised of oil-derived merchandise. One barrel of oil is roughly 300lbs, or 136kg of oil. You want roughly two kilos of polyacrylonitrile (that nylon-esque fibre I discussed earlier) to get one kilo of carbon fibre, so every barrel has in very tough phrases the potential to make 68 bicycles value of carbon fibre.

Extra fast and soiled maths utilizing the Brent Crude value makes a WorldTour bike’s value of carbon fibre value roughly $1. This can be a hilariously small quantity, however do not forget that’s simply the uncooked carbon fibres themselves. There’s the associated fee to run the furnaces to make them, and the related chemistry of the resin, and the delivery of those uncooked supplies to factories to show them into carbon weave earlier than we even get to creating a product.

Signal as much as the Musette – our subscriber-only publication

Metals are completely different, and a bit simpler to grasp. Aluminium, metal, and titanium all happen as deposits of minerals within the earth’s crust, and all want extracting, an awesome diploma of mineral processing, and smelting earlier than you get to saleable metallic. I’ve defined this in additional element in my piece on how bikes are made for those who’re curious concerning the precise manufacturing of uncooked supplies. Metal is normally bought as metal merchandise moderately than ingots (rebar, huge coils, that kind of factor) which barely complicates issues but when we roughly equate ‘Structural Metal’ from the inventory market to the high-quality metal utilized in some ball bearings, chains, and sprockets then we’re £1,300 per tonne, or £1.30 per kilogram. Once more, the uncooked materials price of metal in a motorcycle is tiny, a matter of £1-2, or an identical quantity in {dollars}. You’re wanting on the identical kind of uncooked materials price for aluminium too, and whereas titanium is a a lot larger materials price – within the area of $35-50 per kilogram – there’s far much less of it utilised on a WorldTour bike.

Rubber is a distinct kettle of fish totally, derived as it’s from tree sap. The common rubber value final yr was round $1.50 per kilogram, which is greater than sufficient for a pair of tyres. All in all, simply wanting on the uncooked supplies, a WorldTour bike can price little greater than £30/$40. How, then, can we find yourself with a price ticket north of £12,000?

Manufacturing of carbon fibre

Producing carbon fibres, each the fibres themselves and the pre-woven sheets, from the uncooked supplies primarily includes working a collection of large furnaces. Typically the upper the modulus of carbon (the stiffer it’s) the dearer it’s to supply. Toray is the most important carbon fibre producer available on the market, and it produces all kinds of fibre choices, all labelled with helpful numbers.

T700 is a normal goal, do-it-all fibre and one thing like it will make up the vast majority of a motorcycle body. Larger efficiency frames might go as much as one thing like T1000 or larger, however whereas the body might present the next modulus carbon on the body, equivalent to Toray’s M40X within the case of the Pinarello Dogma, this doesn’t imply the whole thing of the body is made utilizing such fibres. They are going to be reserved for particular areas like the underside bracket. The stiffer the fibres the extra brittle they’re, and so are much less effectively suited to being positioned in advanced areas of the body.

Sadly the principle participant within the carbon fibre world, Toray, declined to be interviewed for this piece, and types weren’t forthcoming both. We are able to nonetheless make some educated guesses right here although, as it’s potential to purchase carbon fibre in small portions as a client. A motorcycle body wants about 1kg of carbon fibre when you account for the offcuts wasted as a part of the manufacturing course of.

Small scale sheets of T700 carbon weave work out at round €15/m2 and weigh about 150g/m2. Taking a full bike at 1000g for straightforward maths meaning a motorcycle body utilises roughly 10m2 of weave in ballpark phrases, or round €100 in carbon price. Larger modulus carbon like T1000 or M40X as is utilized in larger spec frames may be 2-3x as costly, however solely makes up a small (5-10%) portion of the body by mass, and this enhance in price would doubtless be offset by the far cheaper wholesale price for manufacturers utilizing vastly larger portions of carbon fibre than single shoppers should buy.

Chatting with Andrew Juskaitis, Big Bicycle’s worldwide Senior Product Advertising Supervisor I used to be informed {that a} bike just like the Big TCR includes 36m2 of carbon fibre sheet. At €15/m2 this may imply it’s about €540 in carbon, however Big, being the most important producer of carbon bicycles, is of course not going to be paying the identical price as you or I might if we wished to purchase the odd little bit of Toray off eBay. For the sake of argument, let’s spherical this €100 determine as much as £200 to cowl not simply the carbon within the body, however the resins too.

Analysis and growth

Talking with Federico Sbrissa, the Chief Advertising Officer at Pinarello I requested him how a lot growth useful resource goes into one thing like the brand new Dogma. Whereas the group gained’t work solely on one factor on a regular basis, I used to be informed that the most recent Dogma took the equal of the entire R&D group of seven folks one full yr of labor, not together with any exterior advisor prices like outsourcing wind tunnel testing.

In response to payscale.com, the common wage for an Italian Design Engineer is €40,000/yr, that means that in R&D prices alone a brand new top-end street bike prices within the area of €280,000 (roughly £230,000 or $300,000) in wage prices alone. Think about a while within the wind tunnel, that are industrial models as we all know from our personal wind tunnel checks and also you’re one thing within the realm of £300,000. A model like Specialised can minimize the price of industrial wind tunnel utilization by merely constructing its personal wind tunnel, however the price of constructing a wind tunnel isn’t precisely small…

An enormous quantity for certain, but it surely all is determined by how skinny you unfold the jam. If the model in query makes extra frames this price is unfold extra thinly throughout every particular person body. Fewer bikes, larger price per body. Sbrissa, whereas being extraordinarily useful, declined to inform me what number of Dogmas Pinarello produces so let’s ballpark it at 2,000 frames a yr over a 3 yr product life, broadly in step with a determine Rob Gitelis of Issue Bikes supplied to Escape Collective in a current article, that’s £50 per body.

Price of manufacturing

Just lately I took a go to as much as the Nationwide Composites Centre, simply north of Bristol right here within the UK. It was a truth discovering mission for an additional piece I used to be engaged on, however whereas I used to be there I picked up loads of bonus details about how carbon fibre merchandise are made. I’m going to focus in on carbon fibre primarily right here for a bit, because the manufacturing is barely extra advanced, and apart from small scale titanium outfits and deep customized metal, many of the very costly bikes available on the market are carbon.

Each carbon fibre product wants what’s often known as ‘tooling’, which is the business time period for the mould wherein the uncooked fibre sheets are laid earlier than going into the strain cooker. For a body, you’re one thing within the area of £30-50,000/$65,000 for a single measurement (not essentially a single mould, however multiples of the identical measurement mould to permit multiple body to be produced without delay. For those who’re an organization making an all-new mannequin in a run of six sizes that’s £300,000/$400,000 simply in the price of the moulds. With this alone in thoughts, it’s now a bit simpler to conceive of why the distinction between the uncooked materials price and the price of a completed product is so nice. For those who take a motorcycle just like the Pinarello Dogma, which is obtainable in 11 sizes, that would add as much as over half one million kilos simply in the price of the moulds.

Taking a conservative determine of £300,000 for the outlay for the price of the tooling and dividing that whole price by our ballpark determine of 6,000 frames (2,000 per yr for 3 years) that’s £50 per body.

Not an enormous price on a per-frame foundation, however a large outlay up entrance, and so some manufacturers get round it through the use of what’s often known as an ‘open mould’ system. Bike factories have off-the-peg moulds prepared, and the model can then simply spec the carbon it needs for use, the layup, and crucially the extent of high quality management. Utilizing this method means no outlay for moulds, and if it is not attempting to make a class-leading superbike a comparatively easy layup will probably be simpler and require decrease ranges of QC to verify it’s secure.

It is this final level that could be a actual differentiator between low-cost and costly carbon bikes. A faux body from AliExpress, or perhaps a no-brand open mould choice has no model related to it. No model means no one to level to and probably sue if or when it fails. No danger, so no actual want to speculate money and time into rigorous QC procedures.

That is compounded by the truth that it’s practically inconceivable to mechanise the manufacturing upon getting the moulds. Producing a carbon fibre body includes items of pre-cut carbon weave being positioned by hand into the best place, in the best sequence, with none wrinkles or shears. It’s extremely labour intensive, and that is why virtually all manufacturing takes place within the Far East, the place wages are decrease. The extra sophisticated the form the longer it takes to layup, and with more and more stiff carbon fibre (larger modulus, as it’s referred to as) the problem is compounded as these are extra susceptible to cracking. Stiffer carbon makes for stiffer bikes, however with this elevated stiffness comes a rise in brittleness too.

Issues are a bit extra easy in the case of the manufacturing of high-end metallic elements. Titanium and even aluminium may be 3D printed now. Colnago makes use of a manufacturing facility in northern Italy that usually produces medical implants. The machines are already there making one thing else and simply want a brand new mannequin loaded into them. Machining, forging, all may be mechanised extra simply and at small scale and as such you will discover much more small scale part producers utilizing metallic than you’ll with carbon. Tactic, White Industries, Raketa, Paul. Economies of scale nonetheless come into play although, which is why the little-produced £1,000 tactic hubs are dearer than extra broadly seen equivalents from the likes of DTSwiss and others.

There’s an assumption amongst many who carbon fibre bikes are all kind of the identical. Many individuals query why one carbon fibre bike can price £12,000 and one other can price a fraction of that. The tooling price is one factor, with extra intricate shapes costing extra, however the usage of larger power and stiffness carbon fibres to scale back the general body weight comes with added manufacturing complexity. On this level, I consulted the Nationwide Composites Centre immediately.

Typically, lower-end frames use “principally intermediate modulus fibres like T700 with some areas utilizing industrial grades (T300 and comparable) with intensive use of woven materials throughout all elements of the body.” This implies the carbon itself is cheaper, but it surely’s additionally extra forgiving to work with and “requires much less design time to make a good body.” The flip facet to that is that you simply want extra of it to get the specified body properties, and so it can’t be made as mild, or as stiff with out turning into excessively cumbersome.

On the mid vary I’m informed that “frames appear to have settled on spending cash on design and utilizing a single grade of fibre” – usually T700-800 or so – however with a larger emphasis on layup high quality. “This extra cautious use of fibres means they extract higher efficiency from a mid-range materials than much less cautious use of fancy carbon.”

While you get to the highest finish, utilising very excessive modulus fibres and aiming for the bottom weight whereas sustaining power the manufacturing will get extra difficult. ‘The commerce off is extra complexity (and so price) in manufacture and as you optimise the construction you rely extra closely on these small portions of excessive efficiency supplies to have a secure body. That’s the reason high quality management is extra necessary on high-end frames as a result of these supplies should be proper so that they take the masses they’re able to and spare the decrease spec supplies from extra load.’

So whereas on the floor two carbon fibre frames might seem the identical, beneath the paint there are variations in supplies, manufacturing time, and high quality management. To be able to get a deal with on what number of man hours go right into a carbon body I referred to as upon Andrew Juskaitis once more, Big Bicycle’s worldwide Senior Product Advertising Supervisor:

“From creation of the composite sheet to putting the finished bike in a field, it takes roughly 25 hours of hand work to construct a TCR Superior SL.”

With this in thoughts, particularly contemplating Big is the most important producer of carbon bikes, producing frames for different manufacturers in its factories, it’s potential to construct a fairly consultant per-frame price in wages.

In response to Bicycle Retailer and Trade Information, the common annual wage for a Taiwanese manufacturing worker in 2022 was $23,697, or roughly $11/hr. Which means every body has a value of $275 in wages, or £213.

This doesn’t embrace the additional price of what is usually a high-intensity manufacturing plant. Water use, electrical energy to run not solely normal energy however the autoclave, common upkeep, and hire all add to this price however are inconceivable to pin right down to a normal expenditure throughout the business.

When a high-end bicycle can simply price greater than a motorcycle it may be a bit arduous to fathom why. Racing bicycles are made to be as mild and environment friendly as potential as a result of the rider is the facility supply. A bicycle owner can push about 0.3 horsepower, which is dwarfed by the output of even a modest motorcycle, and as such motorbikes aren’t made to be so mild. What’s extra, for those who made many elements of a motorcycle out of carbon it will soften.

The structural elements of a motorcycle are, generally, solid and machined to tolerance. This makes use of comparatively low-cost uncooked supplies, and is straightforward to mechanise. The non-structural bits may be manufactured from carbon for high-end race bicycles, however they needn’t be load bearing and so require much less R&D, and as a rule are injection moulded plastic, which is once more simple to mechanise and makes use of extraordinarily low-cost supplies.

Paint

Paint can differ wildly in price, and this was one thing I quizzed Sbrissa about concerning the Pinarello Dogma, primarily as a result of I’ve examined it not too long ago and it is available in a very lustrous paint scheme.

The traditional black with white, or block color, logos I’m informed can price as little as €50 per body, and even much less. Once I visited the Colnago manufacturing facility I noticed first hand how little paint is utilized to a motorcycle just like the Colnago V4Rs in its UAE Workforce Emirates livery, but when we take one thing just like the Dogma in its pearlescent blue then prices start to spiral wildly.

I’m informed the paint itself prices €2,500/kg, or €2.5 per gram. Every body requires a pair of colors to attain the pearlescent impact, including extra up entrance prices, however on a per body foundation it takes round 350g per body, that means the associated fee in paint alone is €875 (approx. £730/$940).

On prime of this, paint is a talented job involving loads of prep time. Sbrissa was naturally unwilling to disclose the wage of the Pinarello paint technicians, however did point out that they have been on the next wage than these within the R&D division. Taking a ballpark determine of €55,000/yr, or round €25/hr, a body that takes 5 hours of labor to finish (what I’m informed is concerned for essentially the most advanced paint schemes) this provides an additional €125 to the whole price of high-end paint, making the whole price primarily a cool, spherical, €1,000, or £830/$1,080 in different currencies.

Pinarello, it have to be stated, doesn’t cost additional for this paint, and I’ve been informed previously that the straightforward black paint schemes are all the time one of the best sellers, and so the cheaper price to supply these subsidises the costly pearlescent choices. Within the identify of tough estimation let’s merely halve that unbelievable £830 determine to £415 to create a mean price. With out understanding the variety of black frames versus pearlescent ones it’s inconceivable to do in any other case.

Elements

Persevering with with the instance of the Pinarello Dogma for now, the mannequin I not too long ago reviewed was about as prime flight because it’s potential to be. Shimano Dura-Ace groupset, Princeton Carbonworks wheels, an built-in cockpit. The works.

Chatting with Sbrissa once more I used to be informed there actually isn’t a lot distinction between what shoppers pay for construct equipment setups versus what a model like Pinarello would pay, particularly making an allowance for the sale costs the business is seeing throughout the board.

The frameset accounts for less than about 35-40% of the price of the bike, which by our calculations up to now is simply shy of £2,000. This doesn’t account for any revenue the model in query is completely entitled to take, in addition to the prices related to working a enterprise which all should be realised by the sale of its merchandise, so this quantity is up to now an unlimited, and really generalised underestimate.

When you add within the componentry price, say £2,000 for Dura-Ace, An additional £2,300 for the wheels, and perhaps £70 for a very respectable set of tyres you’re including £4,370 to the whole price with out even blinking.

Whereas manufacturers will usually spec in-house componentry too, as Pinarello does with its Most cockpit, that componentry nonetheless requires R&D, uncooked supplies, and manufacturing, which do nonetheless add to the associated fee.

Excessive-end parts particularly have develop into dearer. Inflationary prices are one factor, however the easy truth is that hydraulic braking programs and particularly digital groupsets are dearer to supply than their cable-and-spring mechanised forebears.

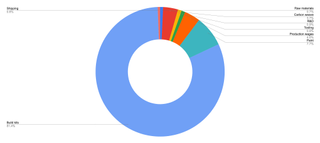

Delivery

If we thought of bikes as a bulk commodity in the identical vein as iron ore and wheat the associated fee per body to ship all around the world would successfully be zero. Big container ships can carry a great deal of 400,000 tonnes, or roughly 57 million 7kg superbikes.

Fortuitously for anybody shopping for a superbike, issues are shipped a bit in another way for industrial cargo. I’m fortunate in some ways to have an exquisite companion, however for the needs of this text I’m additionally fortunate in that her father is Capt. George, a former industrial tanker Captain, who I quizzed about delivery.

“Most stuff is moved by container today,” he tells me, “both a 40ft or a 20ft container. Economies of scale dictate {that a} 40ft container is cheaper. Prices are per container sort, with a fundamental field being the most cost effective, and extra for refrigeration (pointless for bicycles).”

There will probably be an higher weight restrict for every container, although as I’ll get into loads of bikes packaged in containers is empty house for cover, and the bikes are extraordinarily light-weight, it’s unlikely {that a} container even rammed stuffed with bikes goes to hit the burden restrict.

Apparently the associated fee isn’t essentially a case of getting it from A to B:

“Price will probably be dictated by the route and the timeline. Cheaper will probably be an extended timeline, stopping at a number of ports en route, with direct delivery dearer. Costs may be closely impacted by political points, with ships having to alter routes to keep away from piracy or struggle zones, however precise charges may be discovered by digging round on-line: You’ll have roughly 56m3 of house to play with in a single container.”

Armed with that data, plus what I find out about bike containers (on condition that one turns up on the workplace kind of weekly) we will do some extra fast maths.

A motorcycle field is roughly 1560x30x80cm. Some come shipped in my extra compact containers, however it is a fairly good approximation. This can be a whole quantity of 0.36m3, that means in a 56m3 container you could possibly pack 155 bike containers in. Palletising makes issues simpler, so let’s knock that right down to 120 bikes for the sake of argument.

Google is an excellent device, and was swiftly in a position to inform me the present going price for one 40 ft container from Taiwan to Rotterdam within the Netherlands would take round 35 days and between $5.0-$5.5k, or virtually precisely £4,000 to maintain our working whole neatly in the identical foreign money.

Breaking that right down to a per-bike foundation, dividing that by 120 offers us a value of delivery of round £33. This doesn’t account for all the opposite delivery that goes on. Bikes are sometimes despatched from the manufacturing facility in Taiwan to Europe for portray, and parts and uncooked supplies are additionally transported by ship, however you possibly can match an terrible lot extra unpainted, unbuilt bike frames in a 40ft container than you possibly can full bicycles, so the prices are unfold extra thinly per merchandise.

This doesn’t take note of the journey on both facet of the seaports although, as street and air freight are vastly dearer. Air freight, in line with Juskaitis of Big Bicycles, is reserved for less than essentially the most fascinating elements:

“Delivery is, certainly not, low-cost (definitely true throughout the pandemic)). Most items journey by way of ocean freight however a number of, extremely fascinating merchandise, are air freighted to their vacation spot (which is extraordinarily costly).”

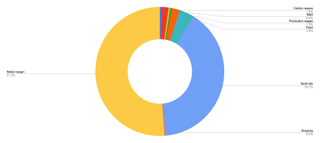

Distribution and dealerships

Historically the bike business labored like this: Model makes bike. Model sells bike to distributor or supplier (distributor then sells to supplier if wants be). Vendor sells bike to buyer. Every step on this course of includes folks getting cash, which is primarily why so many manufacturers have gone direct to client. Canyon is the massive participant on this house, however even Specialised has gone direct to client not too long ago.

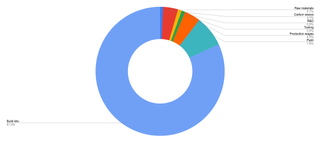

Sbrissa from Pinarello was extraordinarily candid with me once we spoke about dealership prices, telling me up entrance that 40-45% of the price of one in all its bikes is the supplier margin. Which means for a £12,500 Dogma F, £5,625 of that’s the retailer’s margin. This goes in direction of all of the working prices related to a fleet of brick-and-mortar dealerships, employees prices inside them, in addition to aftersales, servicing, and guarantee.

Manufacturers like Canyon get round this by simply delivery bikes on to you from their warehouses. Apparently a Dura-Ace geared up Canyon Aeroad is cheaper than a Dogma F, however not by the identical quantity because the supplier margin I used to be quoted by Sbrissa. The retail price is in the end what shoppers care about as that’s the worth that will get deducted from their financial institution stability, but it surely does kind of stack up that the Canyon is dearer than a Dogma in a bizarre kind of approach.

There are undoubtedly extra extraneous enterprise prices wrapped up in the price of a bicycle. Sponsorship of a WorldTour group like Ineos is undoubtedly an enormous price for a model like Pinarello, however that price is borne throughout the model’s total vary of bicycles – assuming, generally, that professional sponsorship drives gross sales in any respect ranges of the enterprise.

Conclusions

I do wish to make it clear that these figures are merely my greatest, educated guesses for these figures primarily based on the data I’ve been given from a superb few useful and dependable sources. They aren’t supposed to be precise, and there are just too many prices concerned in working a global bicycle model for me to embody in a number of thousand phrases.

That being stated, there’s a widespread thread of feedback underneath each high-end bike all throughout the media panorama: How on earth are you able to cost £XXX for a bicycle??

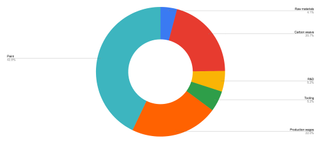

Properly, given my working whole for a prime finish bicycle, that I solely totted up as soon as I had all of the approximate figures in for every stage, got here in at £10,996, I hope this has ultimately shed some mild on that individual query.

For those who subscribe to Cyclingnews, you need to join our new subscriber-only publication. From unique interviews and tech galleries to race evaluation and in-depth options, the Musette means you may by no means miss out on member-exclusive content material. Enroll now.